When it comes to the composition and structure of fluorocarbon aluminum veneer curtain wall, many people may be very interested. The aluminum veneer curtain wall we often see has a very good appearance, and the decorated buildings always make people feel very great. So how is such an outer wall composed.

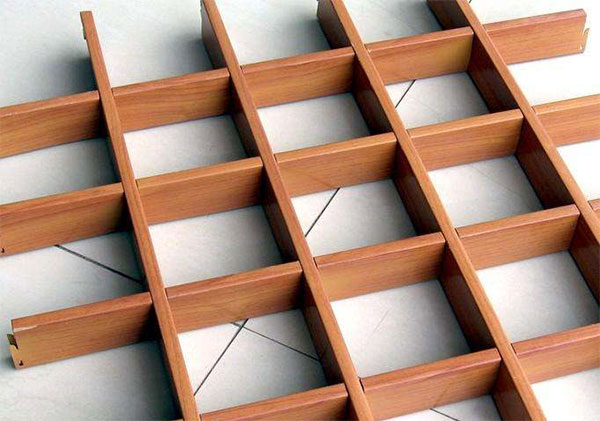

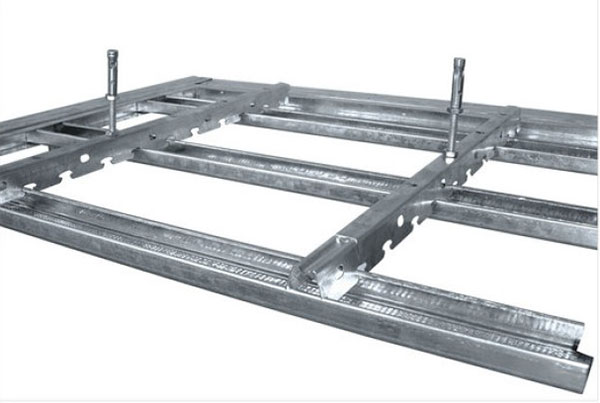

The structure of fluorocarbon aluminum veneer curtain wall is mainly composed of panel, stiffener and corner code. The corner code can be directly bent and stamped by the panel, or riveted on the small side of the panel. The reinforcing rib is connected with the electric welding screw behind the plate surface (the screw is directly welded on the back of the plate surface) to make it a solid whole, which greatly enhances the strength and rigidity of the aluminum curtain wall and ensures the flatness and wind and earthquake resistance in long-term use. If sound insulation and heat preservation are required, efficient sound insulation and heat preservation materials can be installed inside the aluminum plate.

The service life of fluorocarbon aluminum veneer curtain wall is relatively long, so some wall protection is required at this time. In order to make the aluminum veneer curtain wall show the beauty and safety of the building for a long time, the protection of aluminum veneer curtain wall is indispensable. Aluminum veneer curtain wall has excellent self-cleaning and corrosion resistance, so it does not need long-term protection, but it can not be neglected.

Among the decorative materials, fluorocarbon aluminum veneer has been recognized and favored by many entrepreneurs and consumers because of its strong competitive advantage. In recent years, the aluminum veneer industry has developed rapidly, but its price is different for different brands and different materials. Moreover, the quotation range of aluminum veneer price is also large. What are the reasons? Fluorocarbon aluminum veneer manufacturers tell you in detail.

There are many kinds of raw materials used in the manufacture of aluminum veneer, including aluminum alloy, fluorocarbon paint, polyurethane paint and powder. The price of fluorocarbon paint is the highest, followed by polyurethane paint, and the cheapest is powder. Therefore, different raw materials determine the price of aluminum veneer. For fluorocarbon aluminum veneer products. The price of punched fluorocarbon aluminum veneer is slightly lower, while the price of hollow carved or special-shaped aluminum veneer is higher, because process innovation, design innovation and raw material innovation are completely upgraded products!

The decorative effect of aluminum veneer mainly depends on the decorative layer and protective layer on the surface. There are many kinds of decorative layer patterns, such as wood grain and stone grain. Different patterns do not affect the price, but the production process affects the price. It's easier to apply patterns and gloss than the cold coating process. The 180 degree hot covering process launched by Futian aluminum veneer adopts equipment imported from Germany. The pattern has no pixel loss in the transfer process, so the pattern effect is clearer and more transparent like natural marble. In addition, the plane effect is different from the three-dimensional effect. 3D printing makes aluminum veneer present three-dimensional painting, and the cost is higher than that of plane. The price of 3D printed aluminum veneer is higher than that of ordinary aluminum veneer.

In addition to the selection of existing aluminum veneers, consumers can also customize them. Compared with the scale effect of mass production, the customization cost must be higher than that of conventional products, so even for the same material, the customization price is much higher than that of conventional products. It can be customized according to the patterns and effects selected by consumers, so as to achieve a unique decorative effect.

In addition to the above factors, the price of aluminum veneer is also affected by the operating costs of various places, such as logistics and transportation, as well as the premium and after-sales service of different brands. As the saying goes, every other line is like a mountain. Most of the time, what you can see is the surface and what you can't see is the internal quality. Therefore, you can't compare the price blindly when buying aluminum veneers.

What are the main features of fluorocarbon aluminum veneer

As the most common aluminum veneer spraying process, fluorocarbon coating is used for surface spraying to ensure greater advantages in corrosion resistance. However, the main characteristics of fluorocarbon aluminum veneer are reflected in its strong UV resistance, acid rain resistance, salt fog and so on. The characteristics of high spraying uniformity, long service life, simple and convenient installation, and not easy to stain are also obvious. At the same time, it is also a recyclable environmental protection decoration building material. It has the characteristics of good process performance and allows it to be processed into various shapes, so it is favored by customers.

It is precisely because fluorocarbon aluminum veneer is very prominent in characteristics, so it has become the most economical building decoration material, and its reliability advantage is also very prominent. It can better win the recognition of customers, have more obvious advantages in quality, and ensure greater advantages in use.

First process the aluminum plate and then spray it. It can be processed into plane, arc or spherical geometry, so it also has a very good performance in terms of workmanship. In contrast, fluorocarbon aluminum veneer is more cost-effective than previous decorative materials such as glass and ceramics. It can realize 100% recycling of aluminum plate, so it has become the most reliable decorative material for building curtain wall at present.

From the above introduction, it can be seen that fluorocarbon aluminum veneer is very useful in the building decoration industry, and its characteristics are also very obvious. It is also a choice that is more durable and cost-effective than previous building decoration materials. Therefore, it is favored by modern building decoration construction and has become one of the best decoration materials.