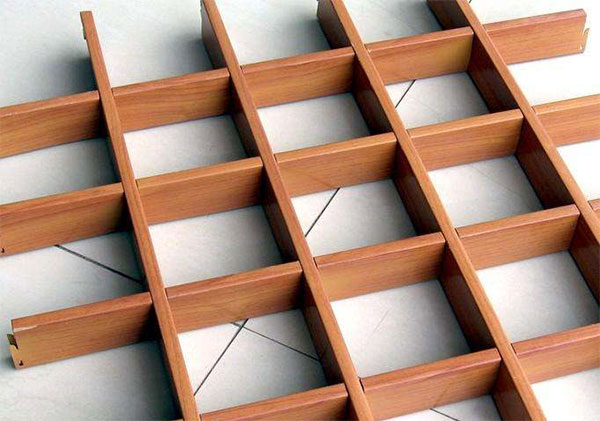

Different height and spacing can be selected when installing different aluminum square links, one high, one low, one sparse and one dense. With reasonable color matching, the design is changeable and different decorative effects can be designed. At the same time, because the aluminum square is transparent, lamps, air conditioning systems and fire-fighting equipment can be placed in the ceiling to achieve a good visual effect.

The installation of aluminum square is simple and the maintenance is also very convenient. Because each aluminum square is separate, it can be installed and disassembled at will without special tools, which is convenient for maintenance and repair.

Specification of aluminum square pipe: the bottom width is generally 20-400mm, the height is 20-600mm, and the thickness is 0.4-3.5mm. Note: the length is customized within 6m, and the special size can be customized according to the specific situation and made manually.

The aluminum square ceiling is mainly made of high-grade aluminum alloy, which is processed and formed by cutting, rolling, spraying and other production processes. The aluminum square ceiling has a transparent structure and excellent exhaust effect. It is installed with one-way strips to form a one-way bottle level vision. It has beautiful shape, bright and elegant lines, and is simple and generous. If the height is properly selected, the visual angle of the space can produce the effect of curtain, which makes the design change thousands of times. The whole building space is spacious and transparent, and has a sense of fashion in the ceiling industry. The aluminum square ceiling is easy to install and maintain the upper fire sprinkler and lighting equipment. It is suitable for modern and simple open public areas.

Characteristics and processing elements of aluminum square pipe

Aluminum square can be divided into aluminum plate aluminum square and profile aluminum square

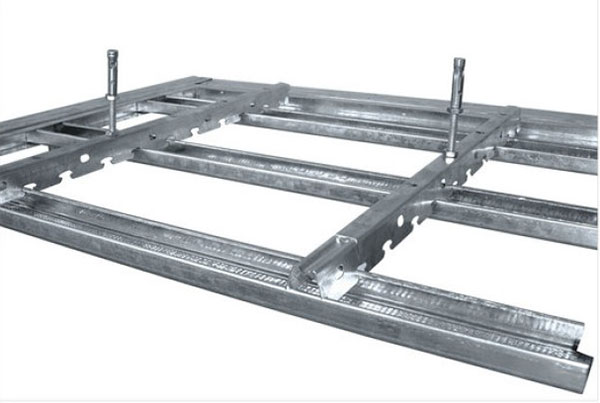

Aluminum plate and aluminum square pass are formed by continuous rolling or cold bending. The device structure is a special keel snap structure. The device method is similar to the general strip gusset plate, which is simple and convenient. It is suitable for indoor decoration (the keel can be planned with wind proof clip code)

The profile aluminum square has the characteristics of ventilation, kneading and forming, and the hardness and straightness of the product are far higher than those of other products. The device structure is the use of the upper main bone, which is connected with the profile hammer with screws and special components. It has strong wind resistance and is suitable for field decoration (the keel distance can be adjusted arbitrarily) The special aluminum square can be pulled and bent into an arc. The presentation of the arc aluminum square provides planners with a broader imagination space to create more common and beautiful works

The aluminum square with different devices can choose different heights and distances, one high, one low, one sparse and one dense. With reasonable color matching, the planning is changeable and different decorative functions can be planned Together, because the aluminum square is transparent, it can place lamps, air conditioning systems and fire-fighting equipment in the ceiling to achieve the perfect visual effect of all

The device of aluminum square is simple, and it is also convenient to protect the same. Because each aluminum square is separate, it can be installed and disassembled at will without special things, which is convenient for protection and maintenance

characteristic:

It is used in public places with complicated shade engineering and dense flow of people, which is convenient for air circulation, exhaust and heat dissipation. It can make the light spread evenly and make the whole space wide and bright It is widely used in open places such as subway, high-speed railway station, station, airport, large shopping mall, passage, leisure place, public toilet, building exterior wall and so on

Specifications:

Specification for aluminum square pipe: the bottom width is generally 20-400mm, the height is 20-600mm and the thickness is 0.4-3.5mm

Note: the length is customized within 6 meters. Special dimensions can be customized according to specific conditions and techniques Unit (mm)

Selection skills:

Top of the list, material

Aluminum materials on the market mainly include the following types: according to the origin of aluminum materials, they are divided into general aluminum materials, Guangzhou aluminum and Southwest Aluminum; According to the world label of aluminum, it is divided into 1100, 3003, 5005 and other labels; According to the alloy strength of aluminum, it is divided into H24, h18, etc; According to the resistance of aluminum, it can be divided into general aluminum, aluminum magnesium alloy and aluminum manganese alloy Most of the ceiling materials sold on the market are made of ordinary aluminum materials, which are characterized by low strength, general flatness, strong resistance and no deformation Without a good base material, the service life of aluminum square will be greatly affected

Second, appearance treatment

The surface treatment of aluminum Fangtong mainly includes the following: spraying, baking paint, roll coating and film coating In the meantime, the service life of spraying and baking paint is short, which is easy to show color difference. The service life of roll coating is in the middle. The coated plate can be divided into general film and imported film. The service life of imported film can basically reach 20 years without discoloration

Third, technology

The so-called process is the bonding of the surface layer of the plate, which is relatively ignored by consumers If the process is not good, it will have a great impact on the service life of products. The treatment processes of aluminum Fangtong manufacturers in the market are very different. Many small factories basically adopt workshop style and reduce the process life When advocating the selection of aluminum square pass, we must understand this one clearly

Three elements of aluminum square pass processing:

There are three important links in aluminum square processing Selection of aluminum plate Aluminum is very important The raw materials for processing Nanjing aluminum Fangtong are high-quality aluminum materials or aluminum alloys

At the top of the list, the raw materials for processing aluminum Fangtong are high-quality aluminum materials or aluminum alloys Southwest Chongqing aluminum is the best, followed by Guangdong aluminum and Shanghai aluminum These raw materials can ensure the surface treatment process of aluminum square pass and directly affect the service life and strength of aluminum square pass

Second, processing equipment and skills Processing equipment and skills are indispensable As long as these two are ensured, the aluminum square pass processing specification can be reached Advanced equipment can ensure the specification of aluminum Fangtong, and high skills can ensure the defective products of aluminum Fangtong Improve production efficiency

Third, treatment process and equipment Advanced imported equipment shall be selected for treatment equipment, which can ensure uniform temperature and common color Reach the surface layer with strong adhesion Not easy to fall Ensure the service life of aluminum square pass