Definition: aluminum honeycomb panel is a sandwich structure, which is made of thin aluminum plates bonded with relatively thick aluminum honeycomb core material to form a hard light plate composite material.

Features: aluminum honeycomb panel has the characteristics of light weight, high strength, especially high rigidity. The rigidity of ordinary aluminum plastic plate and aluminum veneer can not be compared with that of aluminum panel. The surface of the panel is especially smooth, and the decorative effect is especially outstanding as an outer decorative metal curtain wall board. A series of excellent properties, such as zero color difference, sound insulation, heat insulation, non flammable, easy to process and so on, overcome the defects of aluminum plastic plate and aluminum sheet. It is the most ideal building material for exterior wall decoration. It is used more and more widely in the metal curtain wall. Green, environmental protection, energy saving curtain wall materials, our company's aluminum honeycomb plate is all aluminum structure, green and energy-saving building materials, known as the best curtain wall building materials in twenty-first Century.

1. Light weight, high strength, large rigidity, stable structure and good wind pressure resistance.

Aluminum honeycomb panel has been widely used in exterior decoration of buildings because of its light weight, high strength and large rigidity. The weight of the honeycomb sandwich plate with the same stiffness is only 1/5 of the aluminum plate, the 1/10. thickness of the steel plate is 15mm, the panel is 1.0mm, the base plate is 0.8mm, and the weight is only 6 kg / sq. The interconnected honeycomb core is like numerous I-steel, the core layer is fixed in the whole plate, it is not easy to produce shear, so that the plate is more stable, more resistant to bending and compression, its anti wind pressure is greatly beyond the aluminum plastic plate and aluminum sheet, and has the characteristics of not easy to deform and have a good flatness, even if the size of the honeycomb plate is very large, it can also reach a large scale. To a very high flatness. Aluminum honeycomb panels achieve maximum strength and deflection with their minimum weight. With excellent rigid weight ratio, the maximum force is obtained with the smallest material. It is the incomparable characteristic of other materials. It is the first choice of light material in the construction industry.

2. Sound insulation, heat insulation, fire prevention and shock proof

Because the honeycomb core in the honeycomb panel is separated into many closed chambers, the air flow is prevented and the heat and sound wave are greatly hindered. Therefore, the effect of heat insulation, insulation and sound insulation is achieved. The noise reduction of 100-3200HZ can reach 20-30dB and the thermal conductivity is 0.104-0.130W/M.K, so the energy absorption capacity of aluminum honeycomb plate is a kind of ideal energy saving material. In case of heavy rain, raindrops are particularly noisy when they are hit on aluminum veneers or aluminum-plastic panels, and honeycomb panels prevent this.

3, the appearance is straight, the color is diverse, elegant, smooth, durable.

The honeycomb plates of different sizes have very high flatness and have the advantages of non deformation. The aluminum honeycomb plates produced by our company generally use fluorocarbon rolling aluminum plate as panels. The most important point of the fluorocarbon roll coating aluminum plate is the use of continuous roll coating process. The coating of the aluminum plate is completed in one time, to ensure that the product has no color difference, the coating flow is good, and the quality is reliable. At the same time, it can keep the bright colors of the building walls for a long time. After a long period of sun and rain or industrial waste gas pollution, it is obvious that the roll coating board is more clean and brighter than the spray plate, and has good adhesion and weatherability. It is recognized by the World Architecture people as the first flow material.

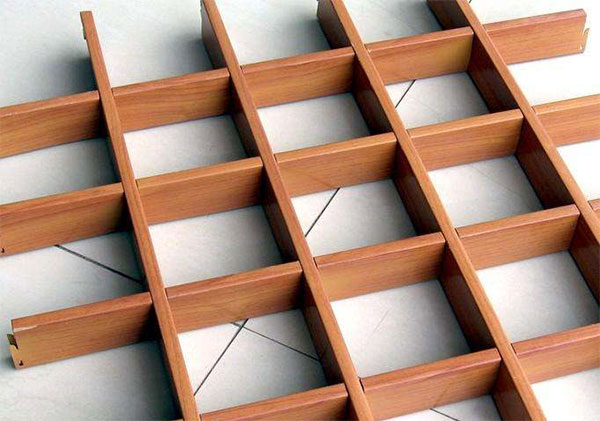

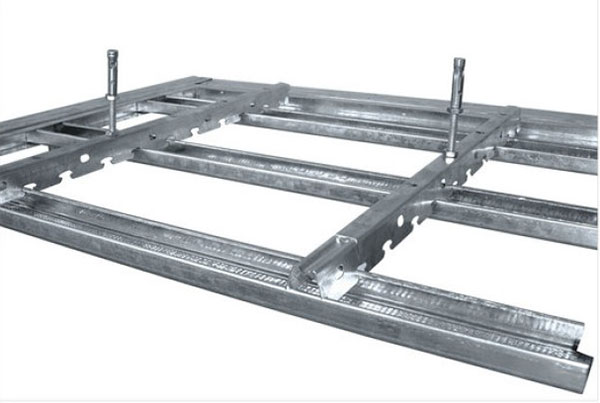

4. Strong decorative, easy to install, quick

Honeycomb panels can be made of different materials, such as aluminum plate, stainless steel plate, color steel plate and natural stone according to different requirements. Curtain wall aluminum honeycomb plate is based on the size of the field design, processed in the factory, after cutting, cutting edge and other CNC machining centers processing, bending around, then compound forming, then punching the ear, hanging ear and plate as a whole, so that the formed honeycomb plate is more firm. Honeycomb panels can be made into flat plates, arc plates and "L" plates. They are all factory produced, with reliable quality, convenient installation and quick installation.

Aluminum honeycomb plate is a composite GB/3880-1997 of alloy aluminum with a thickness of 0.5-1.5mm, and (also with different thickness and different materials on the basis of customer requirements) to use KYNAR500 (containing more than 70% Fluorocarbon) fluorocarbon resin paint; also polyester resin as a surface coating two continuous two bake, coating thickness of 25um + 3um Continuous three coating and three bake, coating thickness of 40um + 3um surface aluminum plate for anticorrosive pretreatment. Aluminum honeycomb panels and soleplates can be selected according to different needs, such as stainless steel plate, fireproofing board, color steel plate, natural stone and so on. Specific specifications and sizes can be designed and manufactured according to needs to meet the needs of various uses.