Introduction of wood grain aluminum honeycomb plate

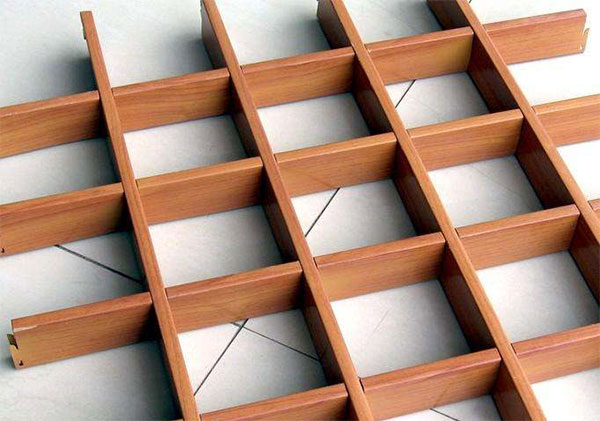

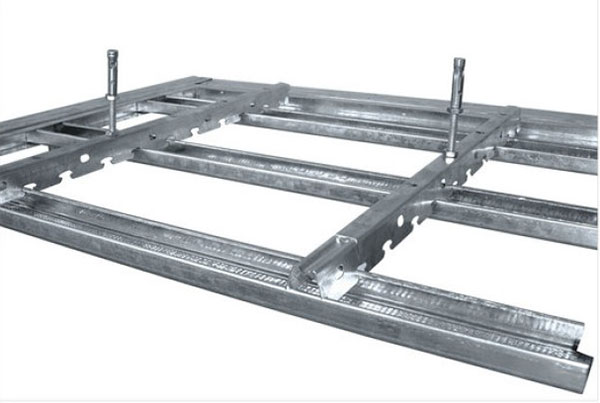

The East European wood pattern aluminum honeycomb panel is transferred from aluminum honeycomb panel and wood grain leather to the aluminum honeycomb panel by overheat transfer, roll coating and laminating process. Wood grain map can be divided into planar grain map and 3D grain map. The grain texture is clear and the effect is realistic. The wood grain aluminum honeycomb plate has the real wood pattern while it has the unparalleled advantages. Its quality is about 211kg/m3, the 1/13 of the building gypsum, the 1/15 of the ordinary cement, the 1/2 of the ordinary honeycomb plate, and the 1/2 of the wood. Taking 18mm thick wood grain aluminum honeycomb plate as an example, the surface density is only 3.8kg/m2; it is larger than the bending rigidity (the ratio of bending stiffness and volume density). The flexural capacity of the 18mm thick fireproof honeycomb plate is equivalent to that of the 4mm thick aluminum plate, which can resist the flexible impact. The aluminum peak nest plate is light in quality, good in toughness, high in strength and good in sound insulation and heat insulation. It is an ideal choice for the ceiling of large project smallpox, and the installation method of aluminum honeycomb plate is diversified. It can be designed for heavy smallpox and can be repaired by people.

Characteristics of wood like aluminum honeycomb plate

Rich and realistic wood pattern

Since the wood grain surface of aluminum like aluminum honeycomb plate is transferred to aluminum honeycomb board by heat transfer, roll coating and film mulching, the user's optional wood grain pattern is very easy to be realized and has a lower cost.

Good sound insulation, heat preservation, heat insulation and fire prevention effect.

Due to the sealing state between the honeycombed honeycombs, the air flow is prevented and the sound wave and heat are effectively hindered. The sound propagation and thermal conductivity of the plate are greatly reduced, so the sound insulation and heat insulation are played, thus the insulation materials are saved, and they are widely used in the partition board or in the ceiling.

Good evenness and rigidity

Because the six corner honeycomb core is in a vertical stress state, and every innumerable fixed honeycomb can not move with good mechanical properties and can not change its shape easily.

Light quality and energy saving

The weight of the aluminum honeycomb plate with the same stiffness is only 1/5 of the aluminum plate, the 1/10 of the steel plate, the total thickness of 15mm, the panel of 1, the aluminum honeycomb plate of the floor 0.8, and the weight of only 6 kilograms per square meter. The total thickness is 10mm, the panel is 0.5mm, and the aluminum honeycomb plate with a bottom plate of 0.5mm is 4 kg per square metre. The weight of the aluminum plastic plate is two kilograms less per square meter than that of the traditional one, but its rigidity is more than two times more than the aluminum plastic plate. It is comparable to the aluminum sheet of 4 millimeter, and its performance price ratio is obviously higher than that of the aluminum plastic plate and aluminum sheet, and the material is effectively saved.