Introduction of fluorocarbon aluminum honeycomb plate

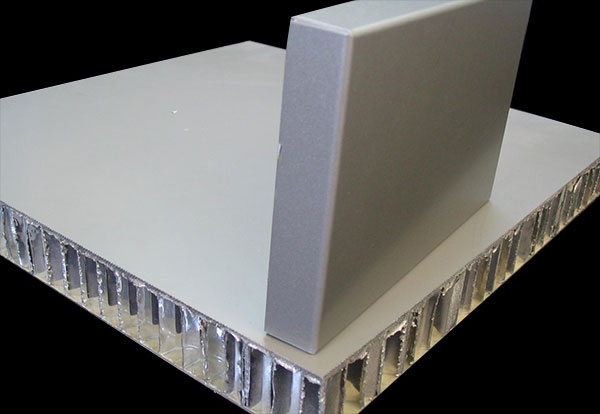

Fluorocarbon aluminum honeycomb plate is a new type of building material, which is composed of aluminum honeycomb core sandwiched between floor and panel, and is used as a ceiling, curtain wall and partition wall. Long Sheng fluorocarbon aluminum honeycomb plate is a new kind of composite made from the advanced German composite equipment and hot melt adhesive. It overcomes the shortcomings of the traditional fluorocarbon honeycomb plate adhesive layer brittleness, low cracking degree, low impact resistance, poor machinability and high cost. It has created a new application market for fluorocarbon aluminum fossa board. The situation.

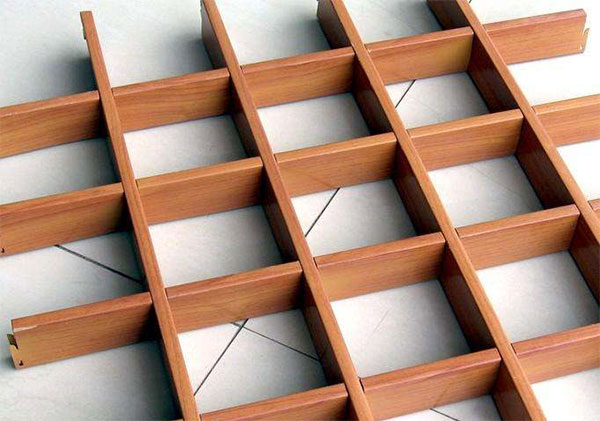

The structure of fluorocarbon aluminum honeycomb plate

Aluminum honeycomb core: using aluminum foil as the base material, it is made up of a lot of dense honeycomb, which can be dispersed from the pressure from the plate, so that the plate is subjected to uniform force, and the strength of the pressure and the high flatness on a large area can be ensured.

Coating aluminum plate: the long full fluorocarbon external wall plate, all of the imported Japanese big gold coating board, fluorocarbon content more than 70%, fluorocarbon resin using the United States PPG fluorocarbon coating, with the best anti acid, anti alkali, anti ultraviolet radiation.

Aluminum alloy plate: the aluminum plate produced by the south-west aluminum plate processing plant, which meets the requirements of the GB/3880-1997 standard, has been cleaned and chrome treated to ensure that the thermal composite bonding is smooth and solid.

Adhesive: the key material of aluminum honeycomb core is the adhesive aluminum panel and honeycomb chip. The adhesive film of our company is made by the DuPont Co of the United States and has ten years quality guarantee.

Characteristics of fluorocarbon aluminum honeycomb plate

Good sound insulation, heat preservation, heat insulation and fire prevention effect.

Because the honeycomb core of the honeycomb between the honeycomb between the seal state, prevent the air flow, make sound and heat effectively impeded, the sound propagation and thermal conductivity of the plate greatly reduced, so sound insulation, thermal insulation effect, thus saving thermal insulation materials.

Good evenness and rigidity

Because the honeycomb core is in the vertical stress state, and every innumerable fixed honeycomb can not move with good mechanical properties. Even if it is impacted by the external force (such as typhoon), the shape of the honeycomb can not change easily.

Light quality and energy saving

The weight of the aluminum honeycomb plate with the same stiffness is only 1/5 of the aluminum plate, the 1/10 of the steel plate, the total thickness of 15mm, the panel of 1, the aluminum honeycomb plate of the floor 0.8, and the weight of only 6 kilograms per square meter. The total thickness is 10mm, the panel is 0.5mm, and the aluminum honeycomb plate with a bottom plate of 0.5mm is 4 kg per square metre. The weight of the aluminum plastic plate is two kilograms less per square meter than that of the traditional one, but its rigidity is more than two times more than the aluminum plastic plate. It is comparable to the aluminum sheet of 4 millimeter, and its performance price ratio is obviously higher than that of the aluminum plastic plate and aluminum sheet, and the material is effectively saved.

Ultra high peel strength

The advanced American DuPont technology and raw materials are used to effectively combine the aluminum plate and honeycomb through high temperature and corresponding pressure. It is improved to excellent state after cooling, so it is not easy to produce dissection at natural temperature.

Environmental protection

The utilization ratio of the coating to paint can reach one hundred percent, the raw material will not remain or spread, the product is resistant to salt acid and alkali erosion, acid rain corrosion, and it will not rot or produce mould. It will never release any harmful gas, will not cause the dragon bone and fixed corrosion, does not need to carry out the repair drawing, and has no side effect on the environment.

Super strong weatherability

Because the surface coating of aluminum honeycomb panels is fluorocarbon polymer coatings, the coating is made of polypropyl two fluorocarbon resin (PVDF), commonly known as fluorocarbon resin. The coating contains more than 70% KYNAR-500 or HY-LAR-500 base material, and the electronegativity 105KJ/mol of fluorocarbon bond in the molecular structure of the fractional {CF2-CH2} is the most stable molecular structure in the present discovery. It has super inertia, so it can resist the corrosion of various air pollutants and acid rain, not be afraid of intense ultraviolet radiation, resist weathering and scour. Brush and corrosion resistance is strong. It can ensure that the coating will not fade or crack for more than 20 years.