An introduction of piercing and sound absorption aluminum honeycomb plate

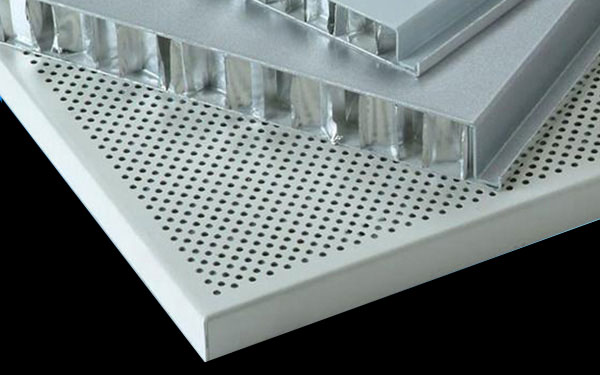

The punching and sound absorption honeycomb aluminum plate adopts a "honeycomb sandwich" structure, which is a composite plate made of high strength perforated aluminum plate with excellent weatherability and decorative coating and aluminum honeycomb core made by high temperature and high pressure.

The structural structure of the piercing and sound absorbing honeycomb aluminum plate is a perforated panel and a perforated back plate. The honeycomb sandwich structure is directly bonded to the aluminum honeycomb core by high quality adhesives and aluminum honeycomb core, and a layer of sound absorbing non-woven fabric is attached to the back plate of the aluminum honeycomb plate. Because the honeycomb core in the honeycomb plate is separated into many closed chambers, the air flow is prevented, the sound wave is hindered, the sound absorption coefficient is increased (up to 0.9), and the strength of the plate is increased, the size of the sheet can be larger and the design freedom is further increased. According to the interior acoustics design, different perforation rates can be designed, and the sound absorption coefficient of the composite structure can be controlled in a certain range, which can not only achieve the design effect, but also control the cost reasonably. Through controlling perforation aperture and hole distance, the perforation rate can be changed according to the requirements of customer. The maximum perforation rate is less than 30%. The diameter of the hole is generally selected as 2, 2.5 and 3. The perforation of the back plate is the same as that of the panel, and the sound absorbing cloth adopts the sound absorbing material such as the nonwovens and sound-absorbing cloth of German co de treasure.

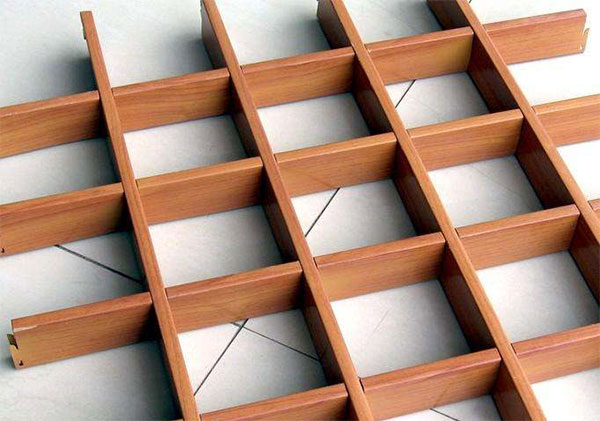

The structure of 1.

The punch aluminum honeycomb plate is composed of aluminum honeycomb sandwich structure with high quality adhesive and aluminum honeycomb core, and the honeycomb sandwich structure is formed by the high quality adhesive and aluminum honeycomb core. The honeycomb core is attached with a layer of sound absorbing cloth between the panel and the back plate. At the same time, the aluminum honeycomb core adopts the hexagonal inherent stability structure, which improves the strength of the plate, makes the size of the single plate larger, and further increases the degree of freedom of the design.

2. sound absorption function

Because the honeycomb core in the aluminum honeycomb plate is separated into many closed chambers, the air flow is prevented, the sound wave is hindered and the sound absorption coefficient is increased (up to 0.9). According to the interior acoustics design, the different perforation rate is designed on the panel, and the sound absorption coefficient of the composite structure is controlled within a certain range, not only is the sound absorption coefficient of the composite structure, but also the sound absorption coefficient of the composite structure is controlled in a certain range. To design aesthetic effect, and reasonable control of the cost. Through controlling perforation aperture and hole distance, the perforation rate can be changed according to the customer's requirement, the maximum perforation rate is <30%. The diameter of the aperture is 2, 2.5 and 3. The sound absorption cloth adopts the sound absorbing material such as high quality non-woven fabric, double sound absorption design and good sound absorption effect.

3. performance characteristics

The aluminum honeycomb pierced sound absorption board has six angles aluminum honeycomb core vertical composite aluminum plate, the honeycomb core is in the vertical stress state, and every innumerable fixed honeycomb can not move with good mechanical properties. The rigidity of the aluminum honeycomb plate is greatly enhanced, and the leveling degree of the aluminum honeycomb plate is made in the process of use. Greatly enhanced, Changsheng aluminum honeycomb perforated sound absorbing board can achieve maximum 1300mm*2400mm.

High strength and light weight, the weight of the aluminum honeycomb plate with the same stiffness is only 1/5 of aluminum plate, 1/10 of the steel plate, the total thickness of 15mm, the panel is 1, the floor is 0.8 of aluminum honeycomb plate, and the weight of each square meter is only 6 kilograms. The total thickness is 10mm, the panel is 0.5mm, and the aluminum honeycomb plate with a bottom plate of 0.5mm is 4 kg per square metre. The weight of the aluminum plastic plate is two kilograms less per square meter than that of the traditional one, but its rigidity is more than two times more than the aluminum plastic plate. It is comparable to the aluminum sheet of 4 millimeter, and its performance price ratio is obviously higher than that of the aluminum plastic plate and aluminum sheet, and the material is effectively saved.

The sound absorption effect is good, fireproof and waterproof, because the honeycomb core inside the honeycomb plate is separated into many closed chambers, which prevents the air flow, makes sound waves obstructed, and plays the sound insulation effect, and the sound absorption cotton or sound absorbing cloth between the honeycomb core and the panel and back plate can effectively absorb the sound transmitted from the punching panel. The double sound absorption design improves the sound absorption coefficient (up to 0.9).

The installation is simple and easy to install. Each plate can be disassembled, replaced, and the tower is installed to install the structure, and the installation is convenient. It can improve the working efficiency, shorten the time limit for the work and save the cost of artificial installation.

It can be customized to meet customer needs in terms of size, punch shape, aperture, hole spacing, sound absorption cotton or sound absorption cloth, surface treatment and color, and so on.

Fire resistance is good, because aluminum honeycomb perforated sound absorbing board aluminum products as raw materials, its fire resistance can reach a level.

Two. Application characteristics

1. Large plate and high flatness

2. High strength and light weight of plate

3, sound absorption effect, fire prevention and waterproof

4. Easy installation, each panel can be disassembled and replaced separately.

5, in terms of size, shape, surface treatment and color, it can be customized according to customer needs to meet the individual needs of customers.

Three. Structure material

1, surface material: pre roll coated aluminum roll

2, front: polyester lacquer

3, back: maintenance finishing

4. Core material: aluminum honeycomb core with special anticorrosive treatment. The alloy is AA3003, the thickness of aluminum foil is 0.06mm, and the length of honeycomb core is 6mm

Four, the performance of the piercing and sound absorbing aluminum honeycomb plate

1. Fire resistance: refractory B1 grade (GB8624-2012)

2. Tensile strength: 165 ~ 215MPa

3. Non proportionate elongation stress: > 135MPa

4. The elongation (50mm calibration distance): > 3%

Five. The main points of design and selection

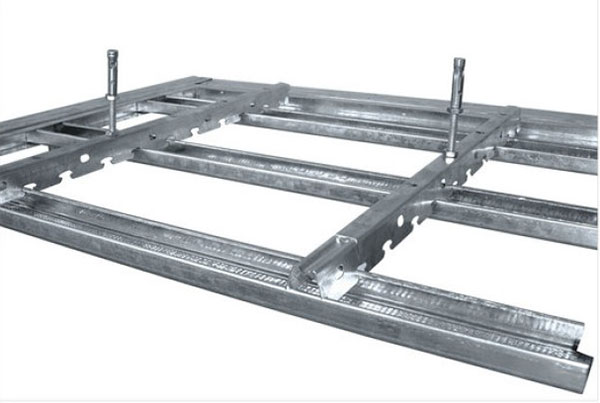

1, the indoor facade or ceiling form must be determined to cooperate with the manufacturer to determine the selection and form of keel.

2, there are a variety of shapes and functions. The shapes are divided into strip, square and various specialties.

3, the installation edge and the non installation edge can be used in combination

4. Each plate can be disassembled and replaced easily.